Building material of digester

Digesters can be made from any of the

following materials:

Steel vessels

Steel vessels are inherently gas-tight, have

good tensile strength, and are relatively easy

to construct (by welding). In many cases, a

discarded steel vessel of appropriate shape

and size can be salvaged for use as a biogas

digester. Susceptibility to corrosion both

outside (atmospheric humidity) and inside

(aggressive media) can be a severe problem.

As a rule, some type of anticorrosive coating

must be applied and checked at regular

intervals. Steel vessels are only cost-effective,

if second-hand vessels (e.g. train or truck

tankers) can be used.

Figure 16: Construction of the digester

neck with steel reinforcement

Photo: Krämer (TBW)

Concrete vessels

Concrete vessels have gained widespread acceptance in recent years. The requisite gas-

tightness necessitates careful construction and the use of gas-tight coatings, linings and/or

seal strips in order to prevent gas leakage. Most common are stress cracks at the joints of

the top and the sides. The prime advantage of concrete vessels are their practically unlimited

useful life and their relatively inexpensive construction. This is especially true for large

digesters in industrialized countries.

Masonry

Masonry is the most frequent construction method for small scale digesters. Only well-burnt

clay bricks, high quality, pre-cast concrete blocks or stone blocks should be used in the

construction of digesters. Cement-plastered/rendered masonry is a suitable - and

inexpensive - approach for building an underground biogas digester, whereby a dome-like

shape is recommended. For domes larger than 20 m3 digester volume, steel reinforcement is

advisable. Masons who are to build masonry digesters have to undergo specific training and,

initially, require close supervision.

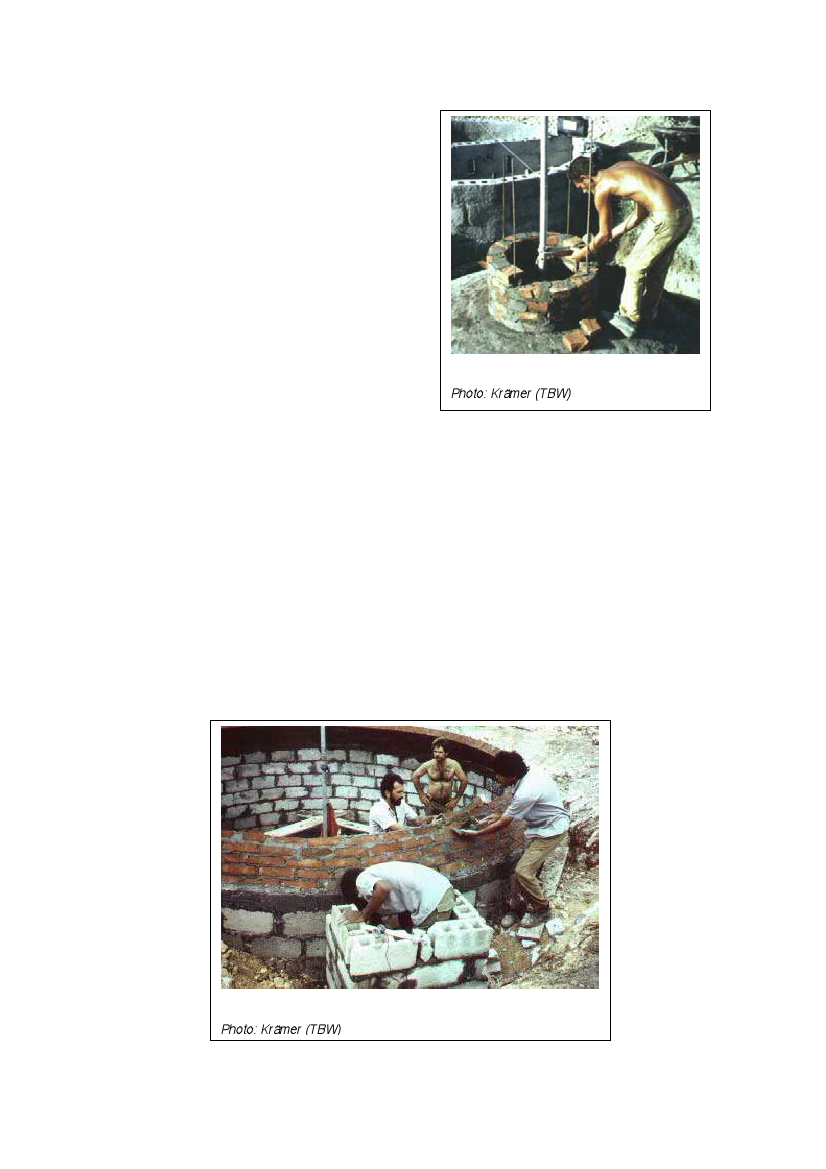

Figure 17: Construction of the dome for a 30 m3 digester in

Cuba

Photo: Krämer (TBW)

21